Green Coffee Beans: Quality vs Defects

Green coffee beans form the foundation of every cup of coffee. Long before roasting or brewing, the quality of green beans determines how flavors will develop in the final cup. For this reason, coffee buyers, roasters, and quality controllers focus heavily on distinguishing between high-quality beans and defective coffee beans. Understanding green bean quality and identifying green bean defects is a vital step in maintaining consistency, flavor, and reputation in the specialty coffee industry.

The Basics of Green Coffee Beans and Quality

When we talk about green coffee beans, we are referring to unroasted coffee seeds processed from the coffee cherry. Their appearance, aroma, and structure reveal a lot about how they were grown, harvested, and stored. High-quality beans usually share several traits: consistency in size, a greenish-blue hue, and a clean fragrance.

On the other hand, green bean defects can show up visually, through irregularities in size, color, or damage. These issues often result from problems in cultivation, poor processing, or improper storage. By paying attention to these visual and physical details, professionals can separate premium beans from defective coffee beans before they enter the roasting stage.

Common Green Coffee Defects Explained

To make evaluation easier, industry experts classify defects into different categories. Each defect has unique causes and noticeable impacts on flavor. Here are some of the most recognized issues:

- Quakers – Beans that are underdeveloped and fail to roast properly. They appear lighter after roasting and taste flat, often with peanut-like notes.

- Black Beans – Over-fermented or damaged beans that turn dark. They add bitterness and unpleasant, earthy flavors.

- Insect-Damaged Beans – Beans with holes or broken edges caused by pests. These defects disrupt roasting and often lead to uneven flavors.

- Moldy Beans – Caused by poor storage, resulting in musty, sour flavors that ruin a batch.

- Broken or Chipped Beans – Mechanical damage during processing, leading to uneven roasting.

Each of these defective coffee beans not only reduces the overall cup score but can also negatively impact the performance of high-quality beans mixed within the same lot.

Signs of Quality: What Professionals Look For

Professionals often evaluate green bean quality with a combination of sight, touch, and smell. Here’s what they focus on:

- Uniformity in Size and Shape – Consistent beans roast evenly, producing balanced flavors.

- Color and Hue – A healthy bluish-green tone suggests proper drying and storage. Yellowish or faded tones indicate age or poor handling.

- Moisture Content – Optimal moisture levels (10–12%) help beans roast well and preserve aromatics.

- Fragrance – Good green beans smell clean, grassy, or herbal. Defective beans often carry musty, sour, or fermented odors.

By checking these aspects, buyers can ensure they are selecting beans that will translate into quality in the cup.

The Impact of Defective Beans on Flavor

One defective bean may seem minor, but when mixed into a batch, it can significantly alter the final flavor profile. For example:

- A few Quakers may flatten the brightness of a coffee.

- Black Beans can introduce bitter and ashy notes.

- Insect-Damaged Beans often roast unevenly, leading to sharp or hollow flavors.

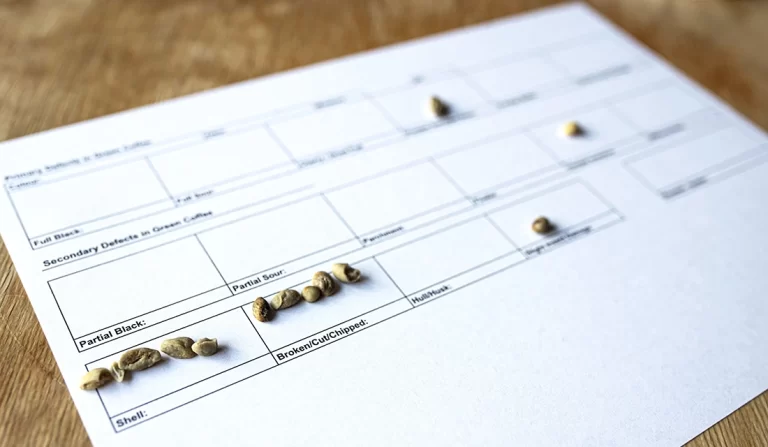

This is why professional graders, using standards from the Specialty Coffee Association (SCA), categorize defects into “primary” and “secondary” to quantify their impact. Maintaining a high ratio of quality beans to defects is what separates specialty-grade coffee from commercial-grade coffee.

How Storage Shapes Quality and Prevents Defects

Even the best harvest can lose quality if beans are not stored correctly. Proper storage is essential for maintaining both physical structure and flavor potential.

- Temperature: Keep beans cool and stable, around 18–20°C.

- Humidity: Maintain relative humidity between 60–70% to prevent mold.

- Packaging: Use jute bags lined with GrainPro or vacuum-sealed bags for longer preservation.

By controlling these factors, producers and traders can reduce the risk of mold, insect activity, or excessive drying, all of which lead to defective coffee beans.

A Different Perspective: Why Defects Matter Beyond Flavor

While defects are usually viewed as negative, they also serve as indicators of process failures. For instance:

- A high percentage of Quakers points to issues with cherry selection during harvest.

- Black Beans often reveal fermentation management problems.

- Insect-Damaged Beans suggest weak pest control measures on farms.

Thus, identifying defects is not only about rejecting beans—it’s about learning where improvements can be made in farming, processing, and logistics. This perspective ensures long-term sustainability and quality enhancement in coffee production.

Conclusion: Quality vs Defects in the Bigger Coffee Picture

Green coffee beans represent the beginning of every cup’s story. Recognizing quality traits and eliminating green bean defects are crucial steps in ensuring excellence for both roasters and drinkers. From Quakers to Black Beans and Insect-Damaged Beans, each defect teaches us something about cultivation, processing, or storage.

At WOD Specialty Coffee, we emphasize education about these differences because they directly affect the journey from farm to cup. In fact, discussions about green bean quality tie closely to the world of competition specialty coffee, where the smallest defect can determine victory or loss. Our WOD blog dives deeper into these competition-level standards, providing resources for professionals and enthusiasts who want to push their understanding of coffee to the highest level.